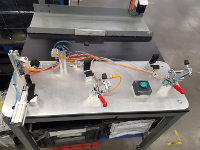

Windshield Wiper Cowl Grille end-of-line tester

We have delivered our R/H and L/H windshield wiper cowl grille garnish end-of-line tester designed and built by us. These units are suitable for checking the shape, geometry of the plastic product and the operator can put the noise reductive stick-on foam as well. If the unit finds everything ok on the final product it will be marked with a stamp.

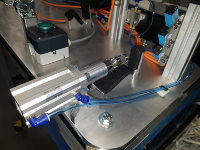

One of the testing units must be able to handle 4, meanwhile the other must be able to handle 2 different products. Instead designing and building 6 separate units, the customer asked us to find out, and design an easy-to -fit seat system. We managed to fulfil all the requirements and designed a quick fit seat system however the sensors not require resetting during product changing to reduce the waste of time.

During the designing process of the machine, we have kept in mind the ease of installation and adjustment, easy and quick replacement of wear parts, and user-friendly handling. In light of this the machine was delivered with easy-to-use digital display.

As we are a flexible and customer focused we have managed to fulfil quickly all the customer requirements that arise either during commissioning or the first use.

As our office is usually providing - we have generated and made all the required documentation for this machine as well. So, the customer got all the documents i.e. engineering statement, technical description, settings manual, exploded view drawings with spare parts catalogue. That were given both on paper or digital format.